This is a natural-processed decaf coffee developed with our partners at Azahar. The coffee has been decaffeinated using a natural substance from sugarcane, called Ethyl Acetate.

Tasting notes: Jammy, baking spices, caramel, dark chocolate fudge ice cream. Plum juice finish. Boozy red fruit and winey plum.

The farmers who contributed to this lot are:

Robert Alexander, Jainiver Montenegro, Jhoan Amesquita, Daniel Garcia, Edier Perdomo, Andres Montenegro, Leider Rubio Herrera, Jailer Andres Trujillo, Julian Molano, Vianey Acosta, Emanuel Avilez, Jhon Faber Canas Villa, Jhovani Parra, Carol Lisbet Garcia, William Avilez Yepez, Yeison Jabela, Estevan Fernando Gomez, Nelly Paola Conde, Fael Rubio.

Origin: Decaf project, Azahar Coffee

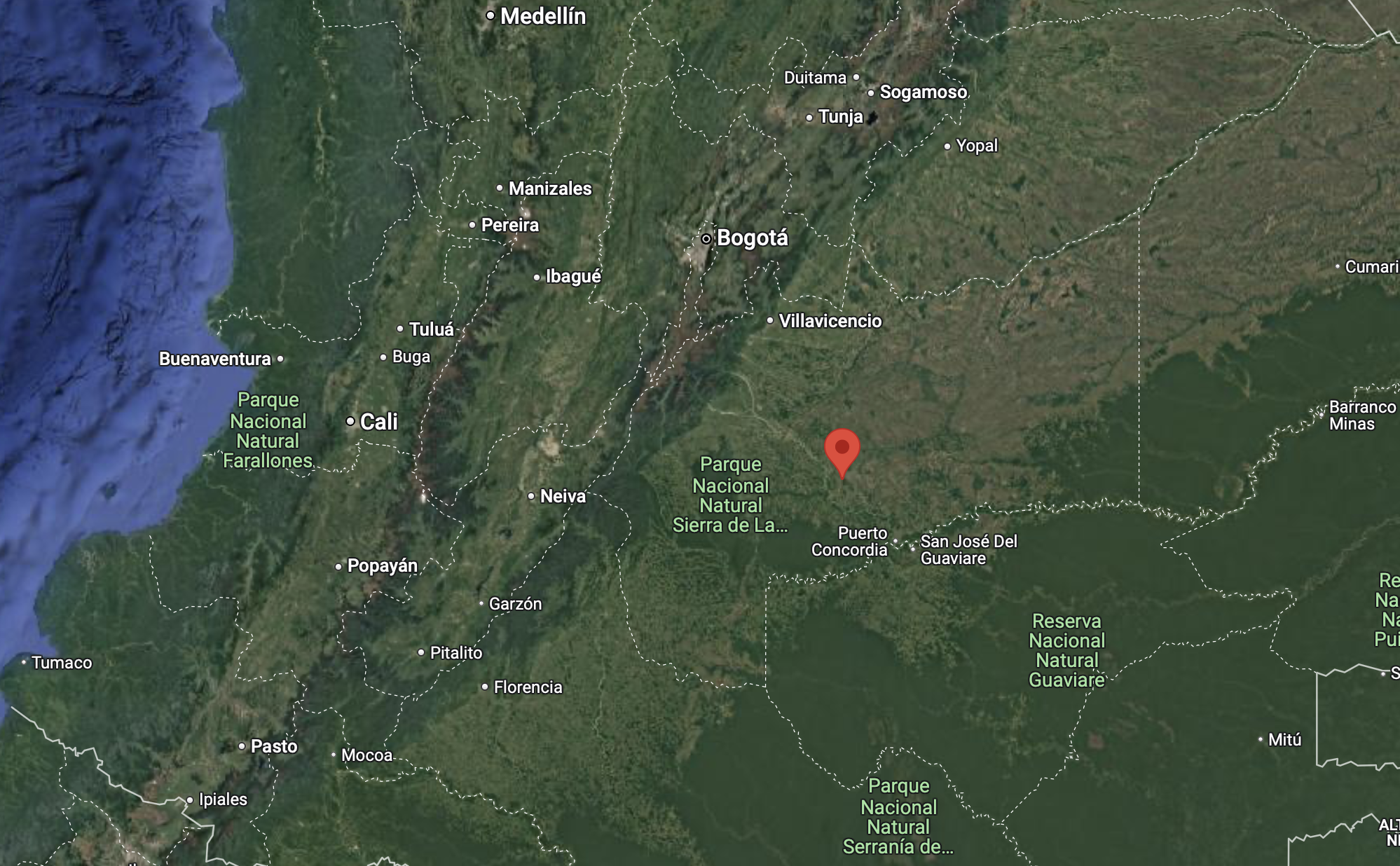

The cherries that contributed to this lot are grown in Huila, at elevations between 1,500 and 2,000 meters above sea level for the washed lots, and between 1,400 and 2,000 for the naturals. The varieties grown on the farms include Castillo, Colombia, and Caturra

.

Decaffeination process

Step 1: The green coffee arrives at the decaffeination plant.

Step 2: In the pre-treatment stage, the coffee is vaporized to remove all the cuticle/chaff.

Step 3: The coffee is moisturized to open its pores, preparing it for the extraction stage.

Step 4: In the extraction tanks, the beans are soaked in Ethyl Acetate (derived from sugarcane).

Step 5: Ethyl Acetate circulates through the extraction tank, removing the caffeine from the beans.

Step 6: The coffee is vaporized again to eliminate any residues of Ethyl Acetate.

Step 7: The coffee is dried back to its normal moisture levels.

Step 8: The dried coffee is transferred to cooling silos to reach room temperature.

Step 9: The coffee is polished with a vegetal wax to enhance and protect its appearance.

Step 10: The decaffeinated coffee is packed and prepared for delivery.