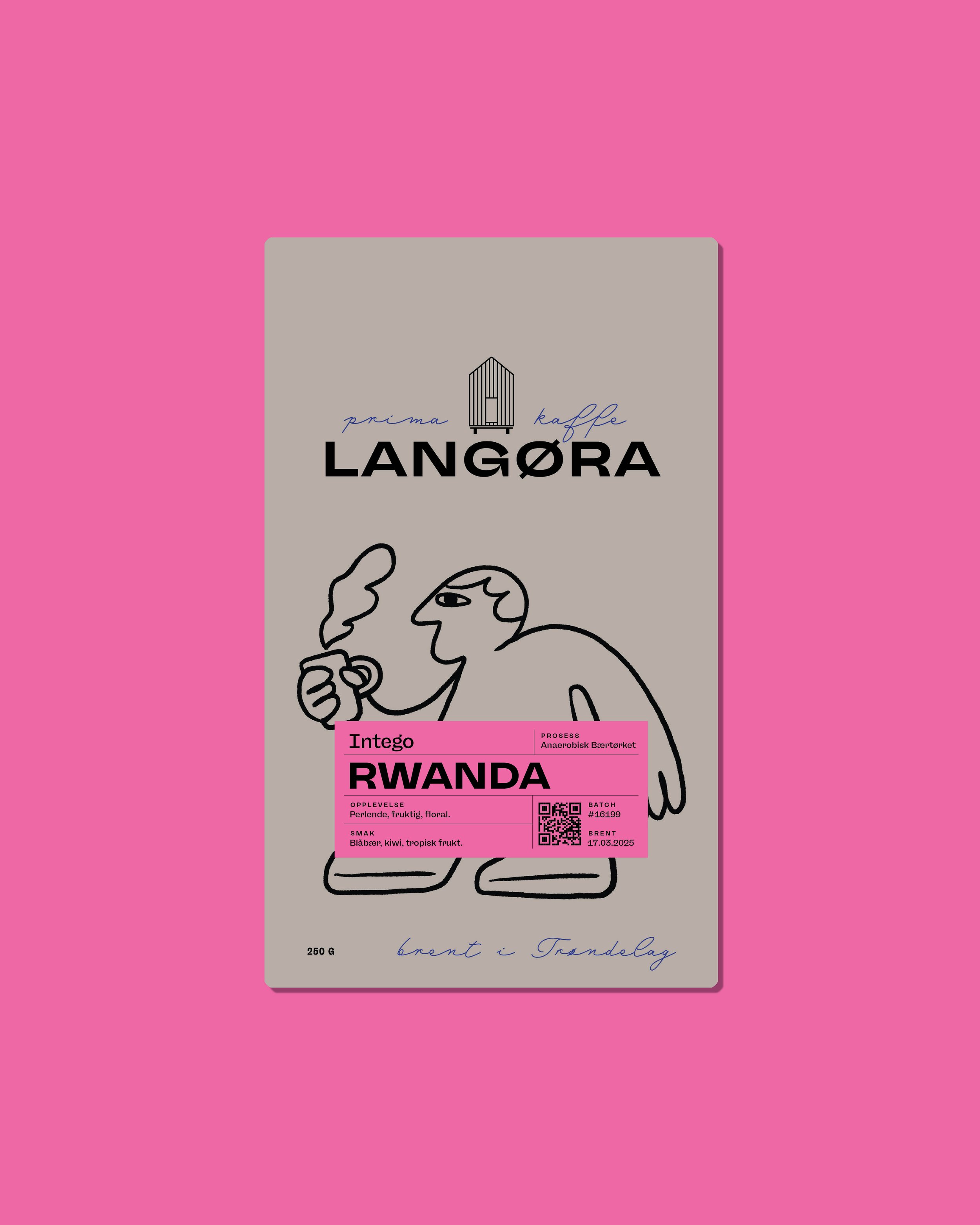

Bilde 1 av

Bilde 1 av

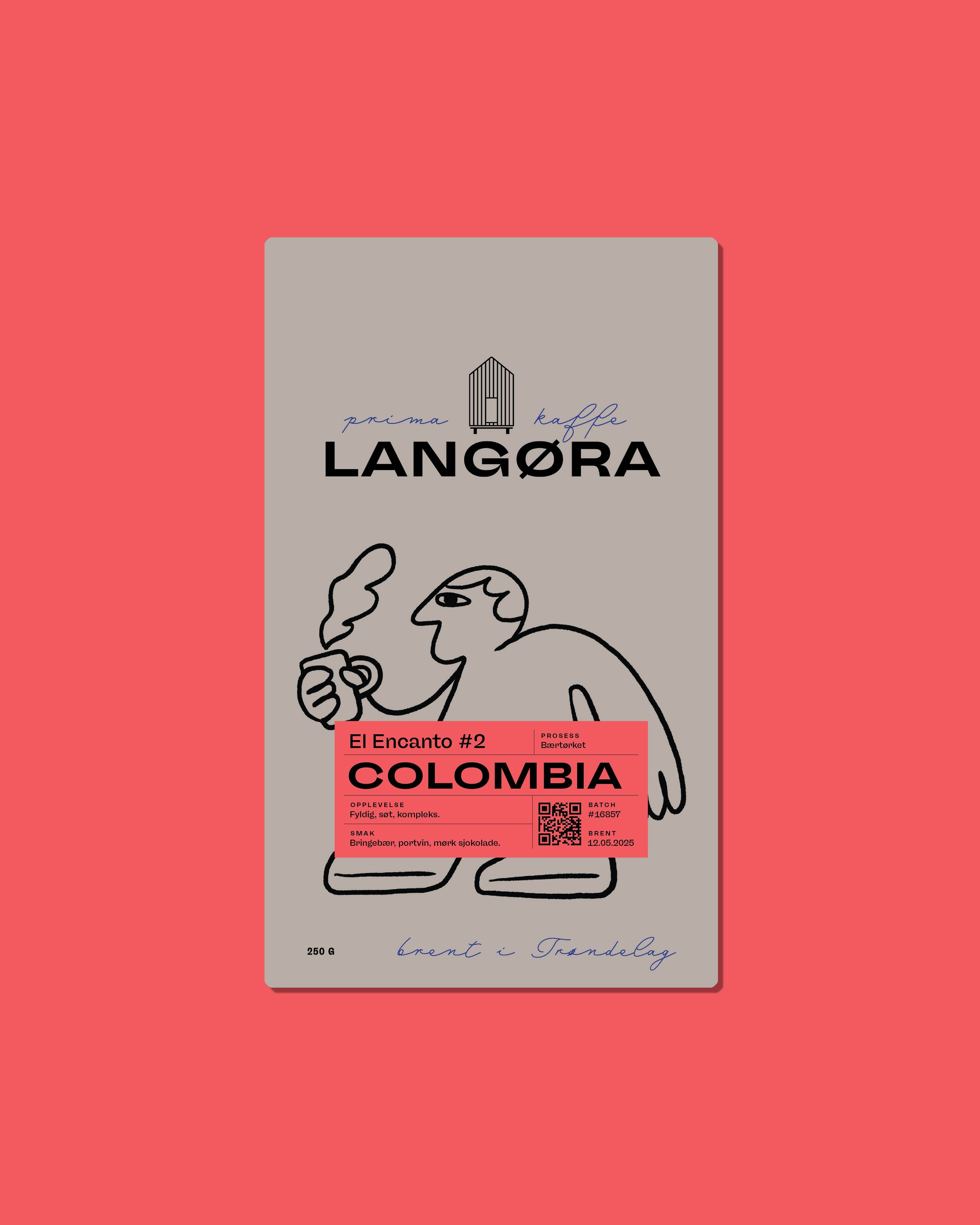

El Encanto #2, Colombia

Fyldig, søt, kompleks.

Bringebær, portvin, mørk sjokolade.

Fyldig, søt, kompleks.

Bringebær, portvin, mørk sjokolade.

Fyldig, søt, kompleks.

Bringebær, portvin, mørk sjokolade.

El ENCANTO #2

COUNTRY: Colombia

FARM:: El Encanto

VARIETAL: Castillo, Tabi, Colombia

PROCESSING: Extended Fermentation Natural

ALTITUDE: 1380-1800 m.a.s.l.

OWNER: Juan Saldarriaga

REGION: Ciudad Bolivar, Antioquia

INFO FROM THE IMPORTER

Origin: Juan Saldarriaga

El Encanto + La Claudina

Juan Saldarriaga manages two farms, La Claudina and El Encanto, each spanning approximately 60 hectares, with a total coffee-planted area of 42 hectares. The remaining land is preserved as forest and a natural reserve.

Juan assumed control of his family's two farms in 2012, initiating the cultivation of diverse and new cultivars, including Castillos, Caturras, Tabis, Bourbons, Geishas, and SL28s, among others. His objective is to understand how each variety thrives in their environment, with plans to expand production of the most successful ones.

Located at 1400 - 1800 metres above sea level, La Claudina is equipped with two pulpers, each with a capacity of 1600 kg of cherries per hour. Traditional fermentation in tanks is a common practice, often involving intermediate rinsing. La Claudina employs three permanent workers and employs 45 seasonal pickers.

El Encanto happens to be his father’s (Luis Saldarriaga) favourite farm. It is exceptionally well kept, and it even features a variety garden that displays the huge range of planted cultivars. This farm spans altitudes from 1380 to 1800 masl, covering approximately 26 hectares dedicated to coffee cultivation. The predominant varieties include Variedad Colombia, Castillo, substantial amounts of Tabi, limited quantities of SL 28, Maragogipe, Geisha, Bourbon, Caturra Chiroso, and Castillo Tambo.

The farm is equipped with a traditional disc pulper featuring a separator and fermentation tanks. For drying, a newly constructed 200-square-metre shelf system offers flexibility to move the coffee between sun and shade.

One of the primary challenges in their region revolves around drying coffee due to high humidity and temperature. In response, Juan has constructed drying facilities with raised beds under cover. He has also invested in a machine that utilises cold air for drying and features software for temperature and airflow adjustments, allowing for tailored drying profiles for different coffee varieties. Notably, improved drying techniques have significantly enhanced the quality of his coffees.

Harvesting

La Claudina and El Encanto (Juan Saldarriaga’s two farms) conduct a single annual harvest typically from September to January. They ensure quality by stripping trees at the end of each harvest, sacrificing some quantity for improved quality.

Picking

Each farm designates one person to oversee pickers and maintain quality control. They implement block-by-block picking and keep batches separate by cultivar. Pickers receive a premium for each bag of high-quality beans. The cherries designated for naturals undergo meticulous hand sorting before the drying process.

Pulping and Fermentation

After cherry selection, the cherries undergo a water soak to remove floaters before processing. Traditional disc pulping with a separator for greens is used. Fermentation methods vary based on tank availability and quantity of cherries. Large quantities, around 5000 kg per day, undergo dry fermentation in tanks with regular water rinsing every 6-8 hours, typically taking 24 hours. For smaller batches and experiments, a new batch of coffee is introduced after 24 hours, extending the total fermentation time to 48 hours.

Drying

Four drying methods are employed: traditional silo (mechanical dryer), cold dryer (mechanical), African beds in a parabolic dryer (greenhouse), and African beds in a shaded drying area. The traditional silo is reserved for conventional and "commercial" qualities.

Microlots from all farms are transferred to La Claudina for drying experiments. The shade and parabolic dryers primarily handle washed coffees, while the cold dryer processes both washed and naturals, with priority given to naturals for their benefit in the controlled environment. Drying duration ranges from 20 to 30 days, with limited space and quantity. They also experiment with honey processing in the shaded area.

In the parabolic dryer, the process takes about 10 to 20 days, focusing mainly on Tabi and some honey processing. The cold dryer accommodates both washed and natural processing, with an experimental temperature range of 25 to 40 degrees Celsius. Most naturals are dried between 25 and 30 degrees Celsius.

Impact

Antioquia is typically known for large coffee estates serving the commercial grade market. However, this region has great potential, with a distinct cup profile that is different from the rest. As the younger generation is beginning to take over, specialty coffee production is evolving.

Juan collaborates with friends to oversee production for nearby farmers, focusing on Caturra and various cultivars up to 2000 metres above sea level. Many of these young, small-scale farmers aim to challenge Antioquia's reputation for producing primarily chocolatey and heavy-bodied coffees. Currently, they are engaged in extensive experimentation to identify what aligns with their preferences and the market demands.

This notion initially emerged with Juan Saldarriaga. When we met him in 2013/2014, he was mostly involved in the commercial market. Being very curious and goal oriented, he got involved in specialty coffee with our guidance. He started out small and experimented with naturals. His plan was a great success, so we worked together to get more coffee growers of the area on board.

Juan has transformed this initiative into a dedicated group of farmers who work together to improve their production protocols, processing, and overall methods. As he is now experienced in experimental processing, he shares the skills he has developed with all of the members. We have already seen an immense advancement in their products and the potential for even more growth.